How to Build a DIY Walk in Cooler With No Floor

Looking to save a few bucks by building your own walk in cooler? This step-by-step guide for building a walk in cooler with NO floor is going to show you how to do just that.

Click here if you're looking to build a walk in cooler with a floor.

Before you grab your hex wrench and get started, it's important you learn how to locate your assembly drawing, handle your panels correctly, and prepare your site.

Sounds like a lot? Don't worry. The video and step-by-step instructions below will show you how to build a walk in cooler in no time.

→ Download Now: The Ultimate Guide to Buying a Walk in Cooler in 2023 [Printable PDF]

One important disclaimer before we dive in...

All electrical and refrigeration work should be completed by a licensed and insured electrician and commercial refrigeration contractor.

Alright, let's get started.

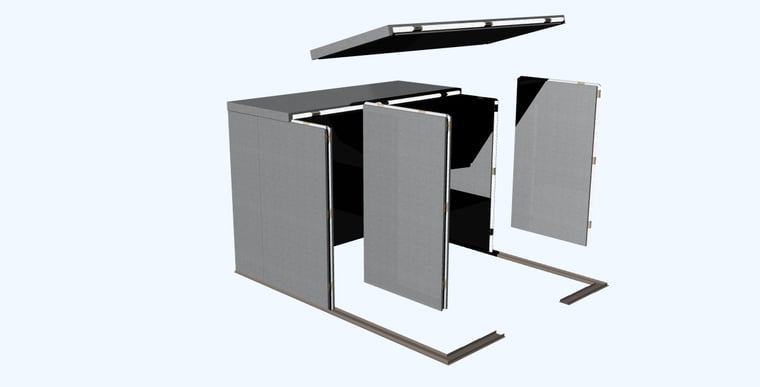

The process of assembling a walk in cooler with no floor is broken down into 4 parts:

- Inspecting and Handling Your Panels

- Preparing Your Site

- Assembling Your Vinyl Screeds & Panels

- Finishing Post-Assembly

Inspecting and Handling Your Panels

Take time to inspect the parts and equipment included in your shipment. Make sure the order number on the boxes and panels match the order number on your invoice.

If you discover damaged parts or equipment, take photos and make a note of the damage on your delivery ticket. Contact your point of sale immediately for further instructions.

Each panel is individually labeled as "wall" and "ceiling".

The assembly drawing included with your shipment, generally found inside the door package, demonstrates the panel layout and shows where each panel goes. This drawing will serve as a reference throughout the assembly process. Keep it handy.

When handling panels, keep them flat and avoid resting them on the edges of the corners to minimize the possibility of damaging them. Stack the panels on an elevated platform if the ground is wet and cover them with waterproof sheathing if you will be storing them outside.

Use 2 to 3 persons during assembly to avoid mishandling panels.

Here is a list of the tools and accessories you will need to complete assembly:

- Hex wrench (included)

- Vinyl screeds (included)

- Vinyl caps for cam lock holes (included)

- Angle brackets to support the door frame (included)

- Power drill (not included)

- Masonry anchors and/or screws for vinyl screeds (not included)

- Silicone sealant (not included)

- Level (not included)

- Right angle square (not included)

- Measuring tape (not included)

- Rubber mallet (not included)

- Hammer (not included)

- Ladder (not included)

- Chalk line (optional - not included)

Preparing Your Site

Site preparation is key to properly building your walk in cooler. Make sure the floor space allotted for your cooler is level and swept clean of dirt and debris.

An uneven floor could result in a faulty assembly with doors and panels not sealing properly. If your floor is not level, you will need to use shims to make it level.

If you are building your cooler inside, adjacent to a wall, leave 3 to 5 inches of space on all sides of your cooler to allow for proper ventilation and at least 6 inches between the refrigeration unit and the ceiling if you opted for an indoor refrigeration unit.

Optional Pro Tip:

💡 Using the assembly drawing as a reference, measure and mark the outer edge of where the vinyl screeds will go with a chalk line. Use a right angle square or measure diagonally in both directions to ensure the measurements match and all corners are at a 90° angle.

Assembling Your Vinyl Screeds & Panels

Review the following "pro tip" before assembling your vinyl screeds and panels.

💡 Use at least two persons when handling and assembling the door panel to avoid mishandling it. Do not remove the door from the door jamb. Doing so will cause the spring-assisted cam-lift hinge to lose the manufacturer's set tension. Keep the door closed and locked until full assembly is complete.

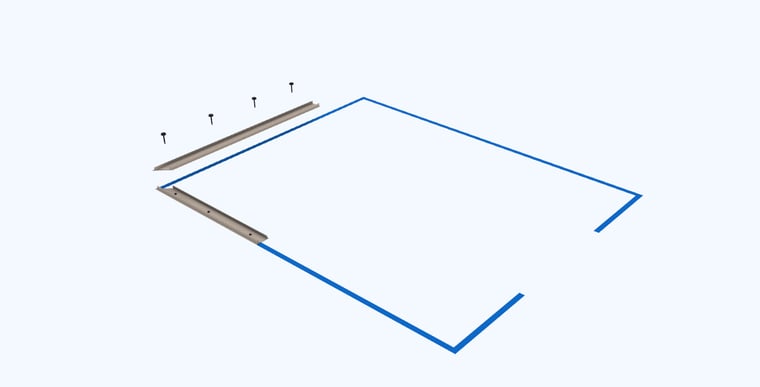

Start your vinyl screed assembly with a rear corner screed as depicted below.

Step 1: Apply a bead of silicone sealant to the bottom of the vinyl screed and line it up flush as per your assembly drawing and the rendering below.

Using a power drill, secure the screed into the ground by inserting masonry anchors or screws every 12 inches. These items are typically not provided by the walk in cooler manufacturer.

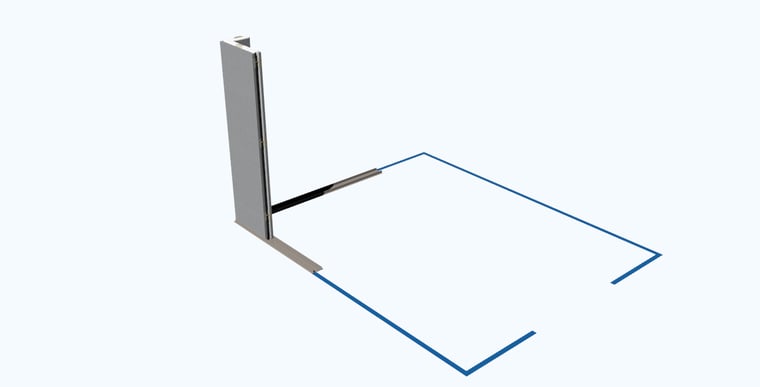

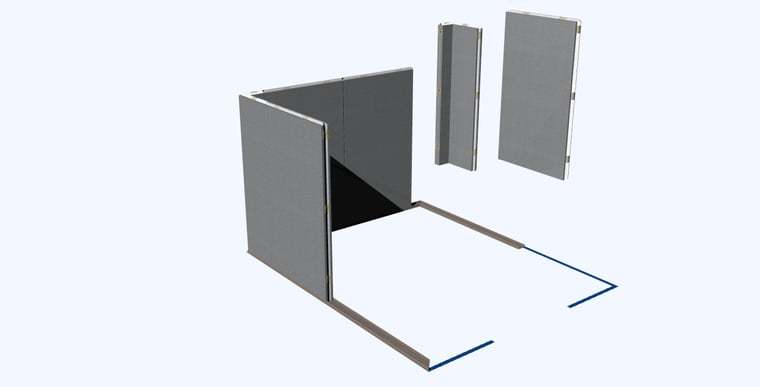

Step 2: Start panel assembly by placing a corner wall panel in the corner screed.

Step 3: Continue adding vinyl screeds in both directions as per your assembly drawing, repeating step 1 as you do.

Make sure your floor remains level as you assemble each additional screed.

Step 4: Place a wall panel on each side of the corner panel and firmly fasten the wall panels to the corner panel using a hex wrench or a drill. Make sure the top of the panels are flush and level before firmly fastening the cam locks.

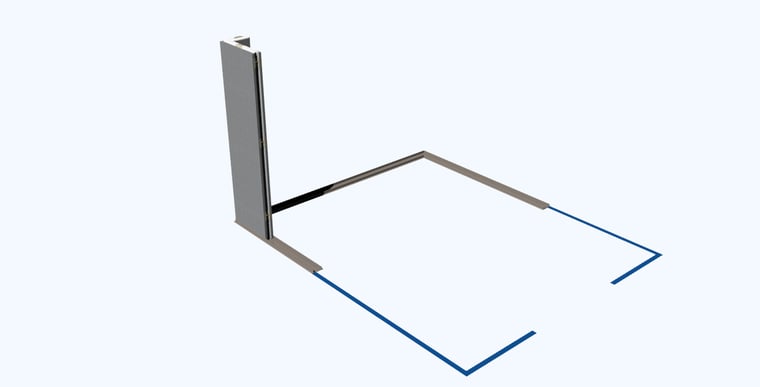

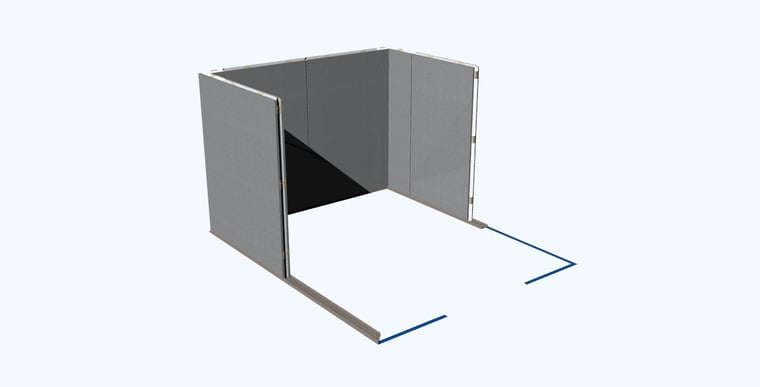

Step 5: Continue assembling vinyl screeds and wall panels as per your assembly drawing. Work your way around the box as per the rendering below. This provides stability as you build your box.

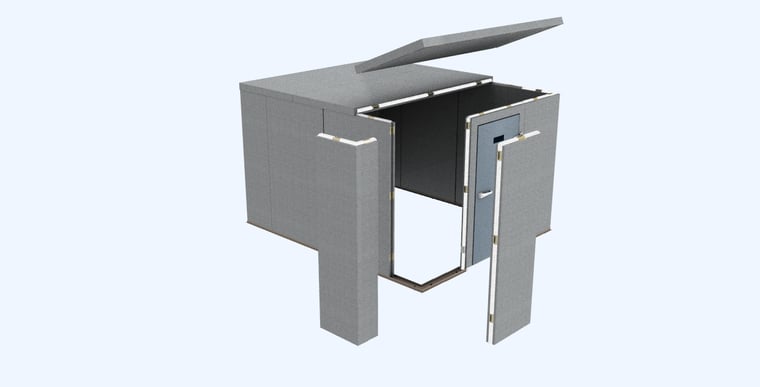

Your box should look similar to this:

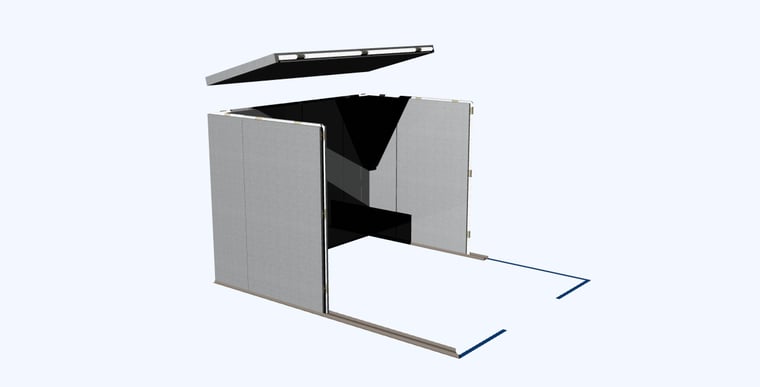

Step 6: Start ceiling panel assembly with the end ceiling panel as per your assembly drawing. Align the ceiling panel with the corners of the wall panels. The tongue and groove method will hold the ceiling panel in place.

Step 7: Continue assembling screeds and wall panels on each side of the box as per your assembly drawing and the rendering below.

Firmly fasten the wall panels to their neighboring wall panels using a hex wrench or drill. Make sure the top of the panels are flush and level before firmly fastening the cam lock.

Step 8: Assemble the next ceiling panel as per your assembly drawing once your next set of screeds and wall panels are in place, aligning the ceiling panel with the neighboring ceiling panel assembled in step 6 and the wall panels you assembled in step 7.

Step 9: Secure the ceiling panels together by firmly fastening the ceiling panel cam locks along the center seam.

Step 10: Continue assembling screeds, wall panels, and ceiling panels as per your assembly drawing. The last screed and wall panel assembled should be a front corner screed and panel.

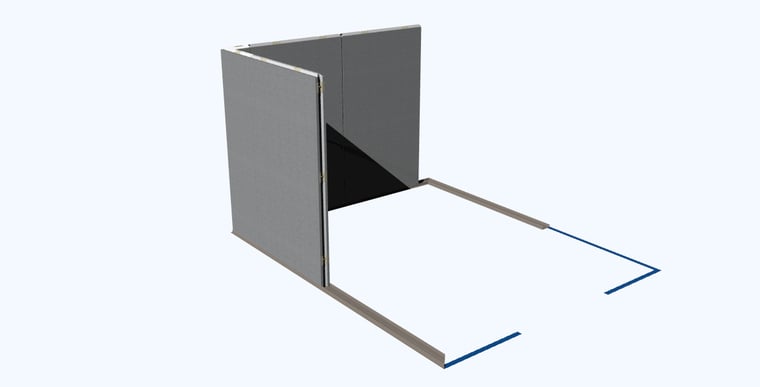

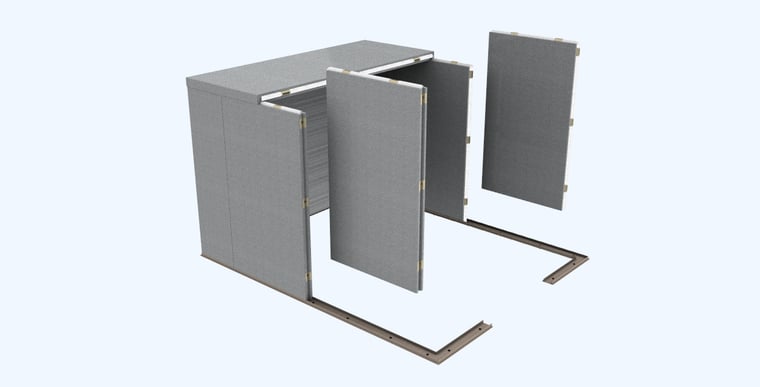

Step 11: Firmly fasten the top of the wall panels to the ceiling panels once all your screeds and panels are assembled, level, and flush at the top.

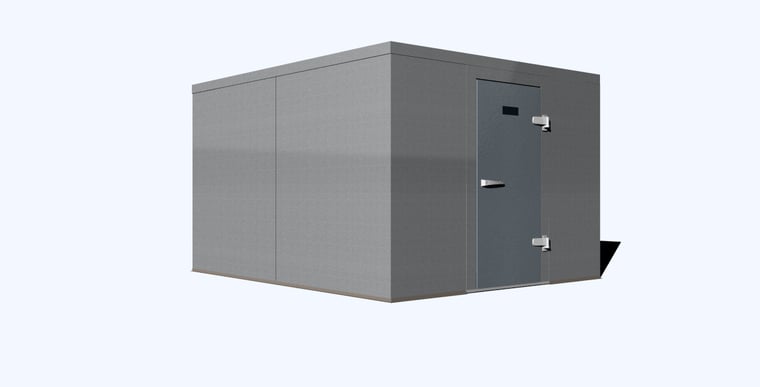

Your assembled walk in cooler with no floor should look similar to the rendering below.

Finishing Post-Assembly

Step 12: Attach the door frame support angle brackets to the floor with masonry anchors.

Step 13: Insert the protective vinyl caps in the cam lock holes.

Congratulations! Your DIY walk in cooler assembly is now complete. Please contact us at 800-327-3371 or adrian@mrwinterinc.net if you have any questions.

Next you'll need a licensed and insured refrigeration contractor to connect your refrigeration unit now that your cooler is assembled.

Learn how to find a reputable refrigeration contractor who can help solve your problems, not create additional ones here.

.png?width=760&height=292&name=Footer%20Image_How%20to%20Buy%20a%20Walk-in%20Cooler%20in%202023%20(1).png)