How are Walk in Coolers Made?

Walk in coolers play a critical role in keeping perishable goods - food, beverages, flowers, plants, pharmaceuticals, etc. - fresh and profitable.

But what exactly is a walk in cooler?

What are walk in coolers made of?

How are walk in coolers made?

Knowing exactly what a walk in cooler is and how one is made will help you make educated, cost-effective decisions and avoid potential pitfalls.

Download Now: The Ultimate Guide to Buying a Walk in Cooler in 2023 [Free PDF]

Whether buying a new or used walk in cooler, all walk in coolers share three core components:

1. Walk in Cooler Panels

2. Walk in Cooler Door

3. Walk in Cooler Refrigeration Unit

Together with accessories like shelves, vinyl curtains, and other items, these core components are tasked with keeping perishables fresh and profitable.

Walk in Cooler Panels

Walk in cooler panels are responsible for maintaining efficient temperature control against warmer temperatures outside the cooler.

They consist of an insulation core with a protective finish and a locking mechanism.

Walk in Cooler Insulation

Walk in cooler panels consist of a 4" to 6" insulation core made of polystyrene or polyurethane.

Polystyrene is a tightly-packed, closed-cell foam with a high resistance to moisture and a strong ability to retain R-value over its life.

Walk in coolers made of polystyrene are often referred to as laminated walk in coolers.

Polyurethane is a porous plastic foam that permanently adheres to its protective finishes. While not as strong at resisting moisture and retaining R-value as polystyrene, polyurethane offers a higher initial R-value while doubling as a fire-retardant.

Walk in coolers made of polyurethane are often referred to as foamed-in-place walk in coolers.

Protective Finishes

The panel's insulation core is protected from the elements by a sheet of protective finish on each side known as a metal skin.

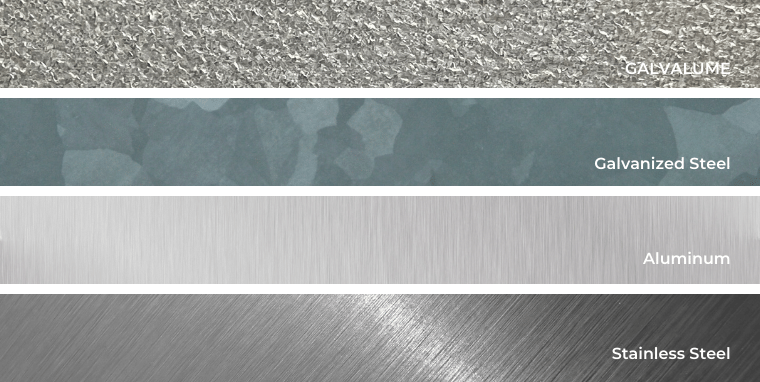

The most common metal skins used are GALVALUME® or ACRYLUME®, galvanized steel, aluminum, and stainless steel. All are highly resistant to corrosion.

GALVALUME® and ACRYLUME® are similar carbon steel base sheets coated with an aluminum and zinc alloy. They are typically offered in 26-gauge thickness with a matte finish and stucco embossed to add strength.

GALVALUME® and ACRYLUME® are the standard protective finishes for walk in cooler walls and ceilings.

Galvanized steel is a carbon flat-rolled steel product with a zinc coating that predates GALVALUME® and ACRYLUME®. It is typically offered in 26-gauge thickness with a silvermatic coating.

Aluminum is commonly used for walk in cooler floor panels due to its ability to withstand loads of up to 500 lbs per square foot.

Stainless steel, the strongest, least corrosive, and most expensive of the protective finishes, is mostly used in high traffic areas where strength and durability are paramount or in settings where sterility is a must.

Locking Mechanism

Most walk in coolers use a cam-action locking mechanism to fasten panels.

Cam locks, short for cam-action locks, are cylindrical fasteners used to hold everything from metal desks to kitchen cabinets together. They allow for walk in cooler panels to fasten without affecting the aesthetics of the panels.

WinClack fasteners, a newer anti-corrosion fastening system, ensures precise, airtight assembly free of gaps and energy leaks. They feature zero metal parts and require no drilling or adhesives for assembly, allowing for easy removal and addition of panels as your cold storage needs change.

Walk in Cooler Door

Besides the obvious - providing access to the interior of a cooler - a walk in cooler door is responsible for sealing tightly to avoid energy loss and overconsumption. It is often the component that sustains the most damage due to wear and tear.

The right walk in cooler door type and size depend on the space available for your cooler and the desired location of your door.

Walk in Cooler Door Types

Swing doors are hinged doors that can be pushed or pulled open from either side. Hydraulic pumps and magnetic gaskets help with self-closing and ensuring the door seals properly. They are suitable for locations with plentiful space.

The width of a standard swing door ranges between 34 and 60 inches. However, swing doors can be customized up to 72 inches wide. Heights range from 76 inches all the way up to 90 inches.

Swing doors can be located on any wall or side of a walk in cooler.

Sliding doors open horizontally by sliding parallel to the wall. They are suitable for tighter spaces and operations that require large openings for pallets and forklifts.

Sliding doors are available in many different sizes and typically located on the center of the front wall of a cooler.

Plug doors, or replacement walk in cooler doors, are used to retrofit existing openings and replace old, worn out doors.

Walk in Cooler Refrigeration Unit

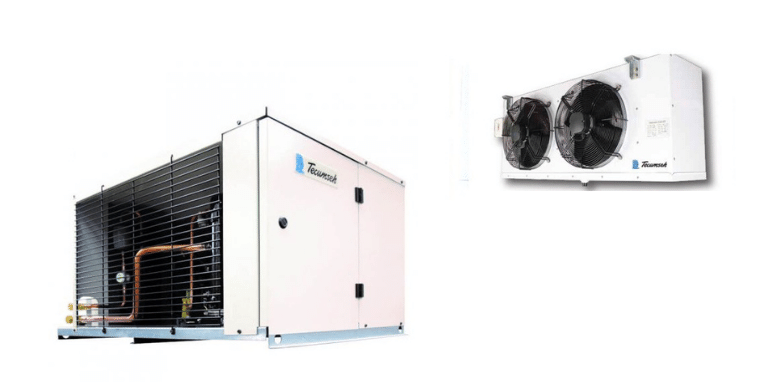

The walk in cooler refrigeration unit is responsible for removing heat and maintaining the temperature inside a cooler between 28°F and 55°F. It consists of a condensing unit, evaporator, and other assembly parts.

Walk in Cooler Condensing Unit

The condensing unit is the portion of the refrigeration unit tasked with removing heat. It is the heart of the entire system, responsible for compressing refrigerant and pumping it to the evaporator in the form of a cold gas.

Condensing units are mostly installed outdoors. However, self-contained refrigeration units are also available for indoor walk in coolers.

Although a compressor is technically a part inside of the condensing unit, the terms walk in cooler condensing unit and walk in cooler compressor are often used interchangeably.

Walk in Cooler Evaporator

The evaporator is the portion of the refrigeration unit tasked with collecting heat inside the cooler and transferring it into a gas. It is typically installed inside on the ceiling towards the rear wall of the cooler.

Walk in Cooler Refrigeration Unit Assembly Parts

Assembly parts connect the condensing unit and the evaporator. They are the unsung heroes that make the magic happen.

A walk in cooler thermostat is a regulating device that senses the temperature inside a walk in cooler and "tells" the refrigeration unit when and for how long to run so the cooler's temperature is maintained at or near the desired setpoint.

The thermal expansion valve is a control unit that regulates the flow of refrigerant released by the condensing unit into the evaporator.

The solenoid valve is a control unit responsible for turning the flow of refrigerant on and off.

The sight glass is a level sensor used to observe the amount of refrigerant contained within the unit.

The filter drier prevents moisture and solid particles from contaminating the thermal expansion valve.

The defrost timer manages the defrost system in the refrigeration unit by activating the cooling cycle and defrost heater to maintain the set thermostat temperature.

Important Note: You could save a few bucks by building your walk in cooler yourself. However, walk in cooler refrigeration units are to be installed by licensed and insured refrigeration contractors only. No exceptions!

In Closing

The good news is you don't have to be a licensed refrigeration contractor or a restaurant equipment expert to have a clear understanding of what a walk in cooler is and how one is made. The more you know, the more educated your decision in choosing the one right for you.

Need help? Talk to a Mr. Winter sales rep today. We've been helping small businesses like restaurants, convenience stores, breweries, bakeries, ice creameries, flower shops, and many others keep perishables fresh and PROFITABLE since 1976.

Now that you know more about the core components of a walk in cooler, take a moment to learn more about which walk in cooler is right for you - Is an Indoor or an Outdoor Walk in Cooler Right for You?

.png?width=760&height=292&name=Footer%20Image_How%20to%20Buy%20a%20Walk-in%20Cooler%20in%202023%20(1).png)